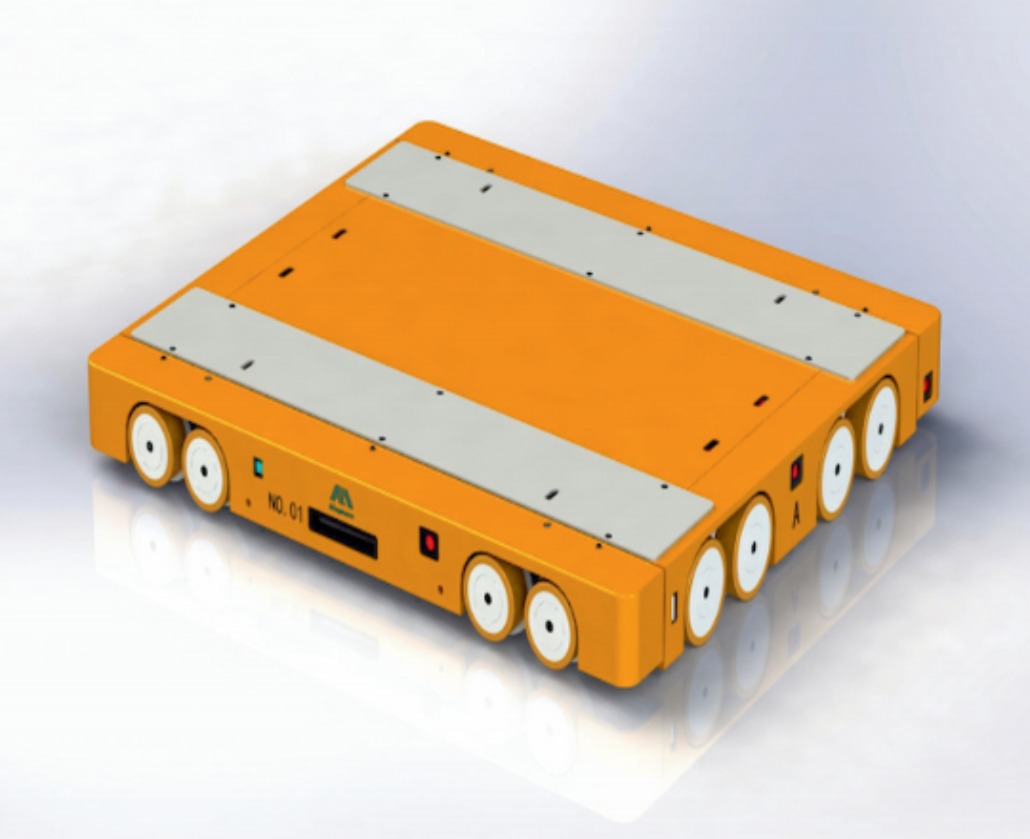

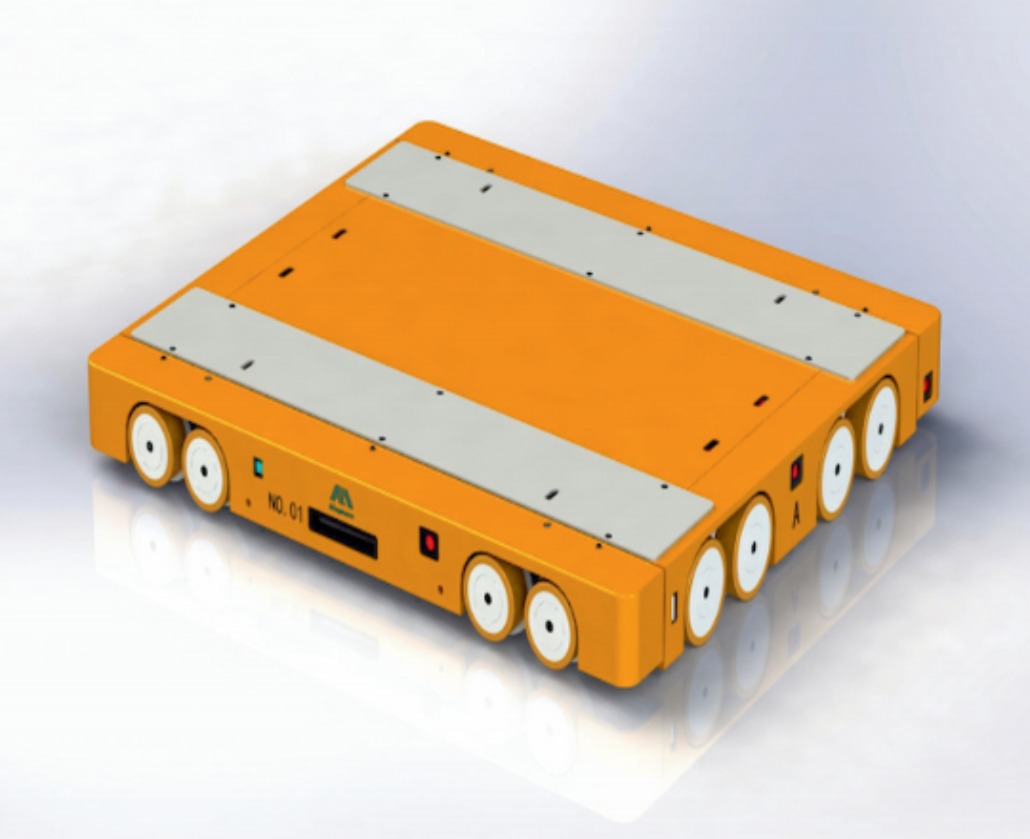

Sistema de trilha de traslado de quatro vias vs. sistema de rack de ônibus bidirecional

Mar 03, 2025

Direção de movimento:

- Shuttle de quatro vias: Pode se mover em quatro direções: para frente, para trás, esquerda e direita. Isso permite operações de armazenamento e recuperação mais flexíveis e eficientes.

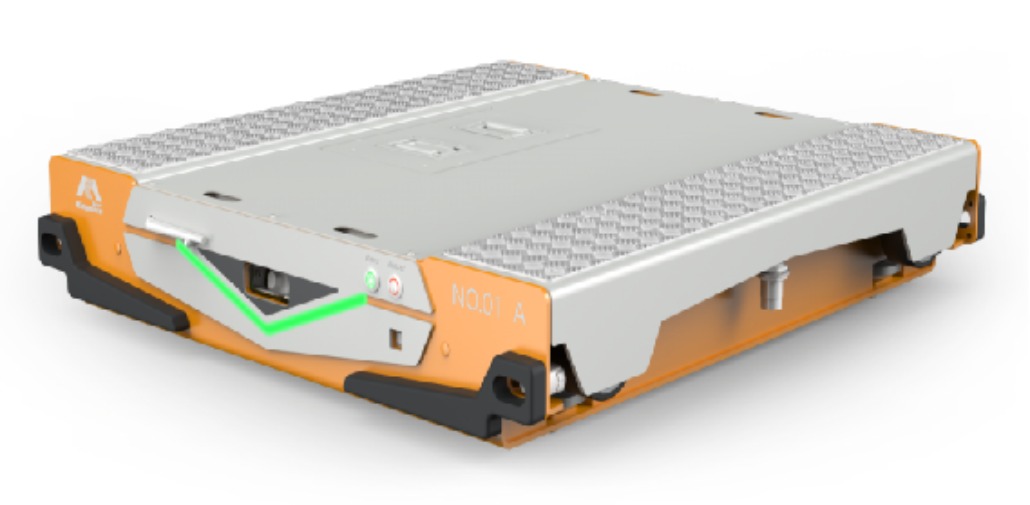

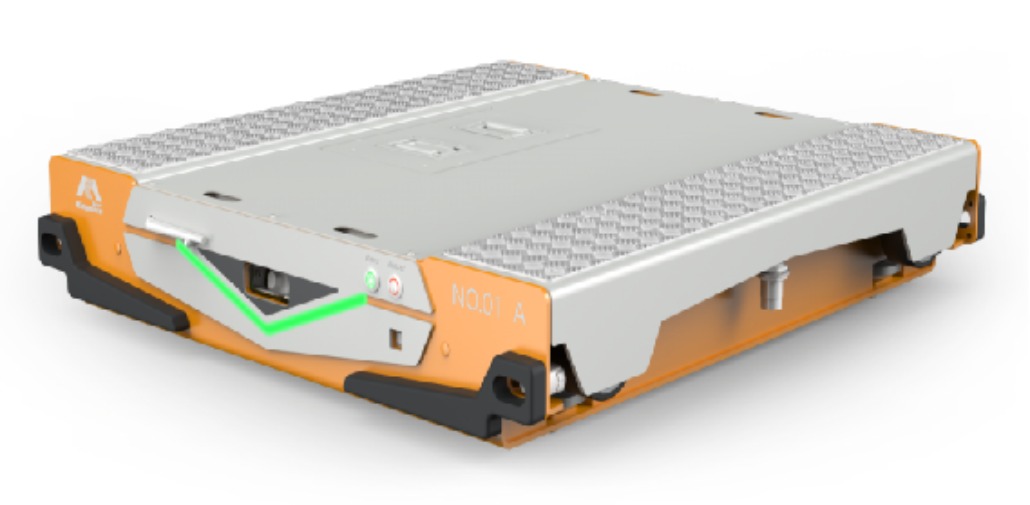

- Traslado de mão dupla: Só pode se mover em duas direções: para frente e para trás. Isso limita sua flexibilidade em comparação com o sistema de quatro vias.

Densidade de armazenamento:

- Shuttle de quatro vias: Oferece maior densidade de armazenamento, pois pode acessar vários corredores sem precisar de equipamentos ou espaço adicionais.

- Traslado de mão dupla: Normalmente, requer mais espaço para manobrar e acessar diferentes locais de armazenamento, resultando em menor densidade de armazenamento.

Eficiência operacional:

- Shuttle de quatro vias: Geralmente, mais eficiente em termos de tempo e trabalho devido à sua capacidade de acessar vários corredores e locais de armazenamento rapidamente.

- Traslado de mão dupla: Pode exigir mais tempo e esforço para acessar diferentes locais de armazenamento, especialmente em armazéns maiores.

Custo:

- Shuttle de quatro vias: Geralmente mais caro devido à sua tecnologia avançada e às capacidades aumentadas.

- Traslado de mão dupla: Mais econômico para operações menores ou armazéns com necessidades de armazenamento menos complexas.

Escalabilidade:

- Shuttle de quatro vias: Mais fácil de aumentar, pois pode lidar com sistemas de armazenamento mais complexos e maiores.

- Traslado de mão dupla: Menos escalável e pode exigir modificações significativas ou equipamentos adicionais para lidar com demandas de armazenamento aumentadas.

Manutenção:

- Shuttle de quatro vias: Pode exigir mais manutenção devido aos seus complexos mecanismos de movimento.

- Traslado de mão dupla: Geralmente mais fácil de manter devido ao seu design mais simples.

Em resumo, o sistema de rack de transporte de quatro vias oferece maior flexibilidade, eficiência e escalabilidade, mas tem um custo mais alto e pode exigir mais manutenção. O sistema de rack de ônibus de duas vias é mais econômico e mais fácil de manter, mas é menos flexível e eficiente, principalmente em ambientes de armazenamento maiores ou mais complexos.

REDE SUPORTADA

REDE SUPORTADA